8.8.23 Newsletter: Backpack Prototypes Readying for Study

Friends of Rumission--

Happy summer to you! We continue to make progress in our efforts to provide the accurate, affordable at scale MRV for enteric methane that the industry needs. Allow me to update you on that progress across various aspects of the business.

Insights

Charm Industrial is the current darling of the carbon credit industry, earning prices upwards of $500 / ton / CO2e. However as I wrote about in a recent blog post there’s no reason enteric methane should not be similarly valued in the carbon markets. In fact enteric methane mitigation shares many of the same attributes that credit buyers find attractive in Charm, except for one key one. Which one? Well I encourage you to read the post (though it may have something to do with measurement …).

Also Seeding the Magic Beanstalk is a podcast focusing on the experiences of early stage entrepreneur. It recently invited Rumission Co-Founder and CTO Kari Klein to share her story, which she did here. Give it a listen to learn more about how Kari’s unique background in atmospheric science and machine learning led to the genesis of Rumission.

Research and Development

Our technology development is focused on preparing our backpack technology for a study next month at the respiration chambers at Scotland Rural College.

Currently no technology can provide detailed (second by second), continuous (for many days on end), accurate enteric methane emission data from many cows simultaneously on working farm conditions. Because our machine learning model requires such data for its training, we have developed such technology in our backpacks. Let’s check in on how the various components are progressing.

Flow Meter

Our backpack requires a device mounted on the cow muzzle that measures the flow or rate of respiration from the cow. We have been fortunate to partner with Dr. Don Jordan and his team. Dr. Jordan is a former faculty member and researcher in Aerospace Engineering at the University of Virginia with a focus in fluid dynamics. Together we’ve developed a device is anatomically designed for cows and is able through differential pressure sensors to measure the flow of their respiration.

The effort began with simulated computer design of the device on top of a 3D cow head model that we scanned:

.png?upscale=true&upscale=true&width=700&name=image%20(8).png) |

The design has proceeded through prototypes placed both on a 3D printed cow head and actual cows:

-1.jpg?upscale=true&upscale=true&width=600&name=Flow%20Experiment%20Image4%20(1)-1.jpg) |

.jpg?upscale=true&upscale=true&width=1000&name=IMG_4364%20(1).jpg) |

In this picture you can see the electronics we’ve developed (more on that below) within the meter, including the differential pressure sensors:

.jpg?upscale=true&upscale=true&width=700&name=Flow%20Experiment%20Image5%20(1).jpg) |

And below you can see the equipment used for the testing and calibration process. The air source and flow rate sensors blow a known airflow through the nostrils of the printed cow head. The Rumission flow meter’s measurements are then compared to this known flow.

.png?upscale=true&upscale=true&width=459&name=Flow%20Experiment%20Image2%20(1).png) |

Sensors & Electronics

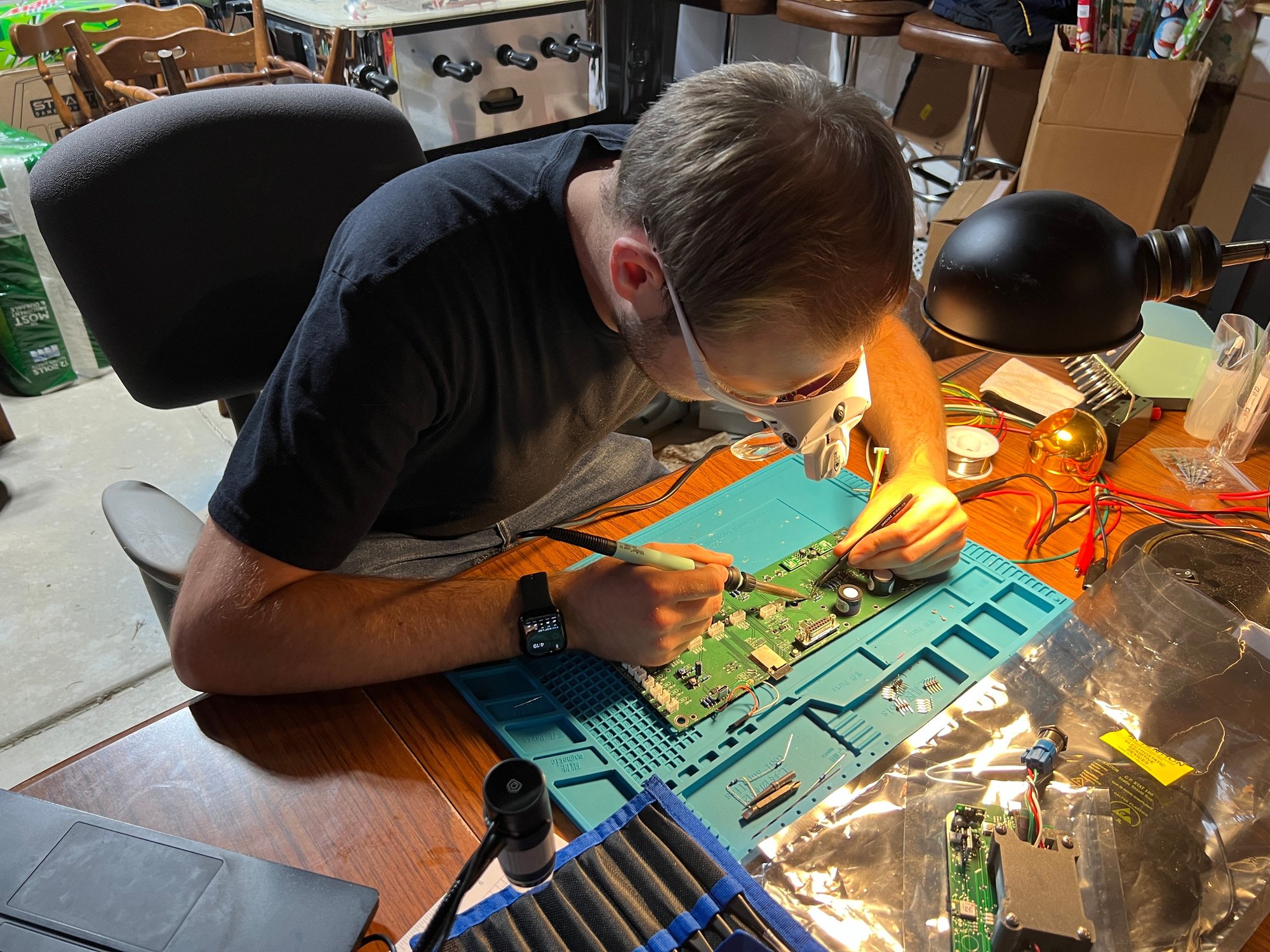

Our backpacks require custom electronic controls to manage the sensors, batteries, and pumps, and to record all of the data captured. Rumission’s Everything Engineer David Kopala has been busy designing, assembling/developing and testing the boards, their components, and their firmware.

Here you can see David plugging away:

|

Here is the laser methane sensor (the silver canister) and main board inside their enclosure along with various pumps and filters:

|

Study in Scotland

The accuracy of our backpacks will be researched in a study at Scotland Rural College, where the backpacks will be placed on cows inside respiration chambers.

Kari is Scotland currently preparing for the study and training the cows:

|

The research will be executed next month after which a scientific paper will be produced in cooperation with Dr. Miller of SRUC and Dr. McFadden of Cornell.

We are excited to develop this research data on our backpack technology, but that is just the beginning for Rumission. For our full MRV solution, the backpacks will provide the training data for our machine learning model, which will enable a small number of sensors measuring cattle emissions in the aggregate to yield the affordable and accurate enteric emissions measurement that the industry needs to proceed with methane mitigation.

We are in the process of organizing more pilots and studies for our technology all over the world, and we’d be eager to talk to you about how our technology might serve your needs.

Regards,

Toby